Architectural Millwork

Custom Architectural Millwork

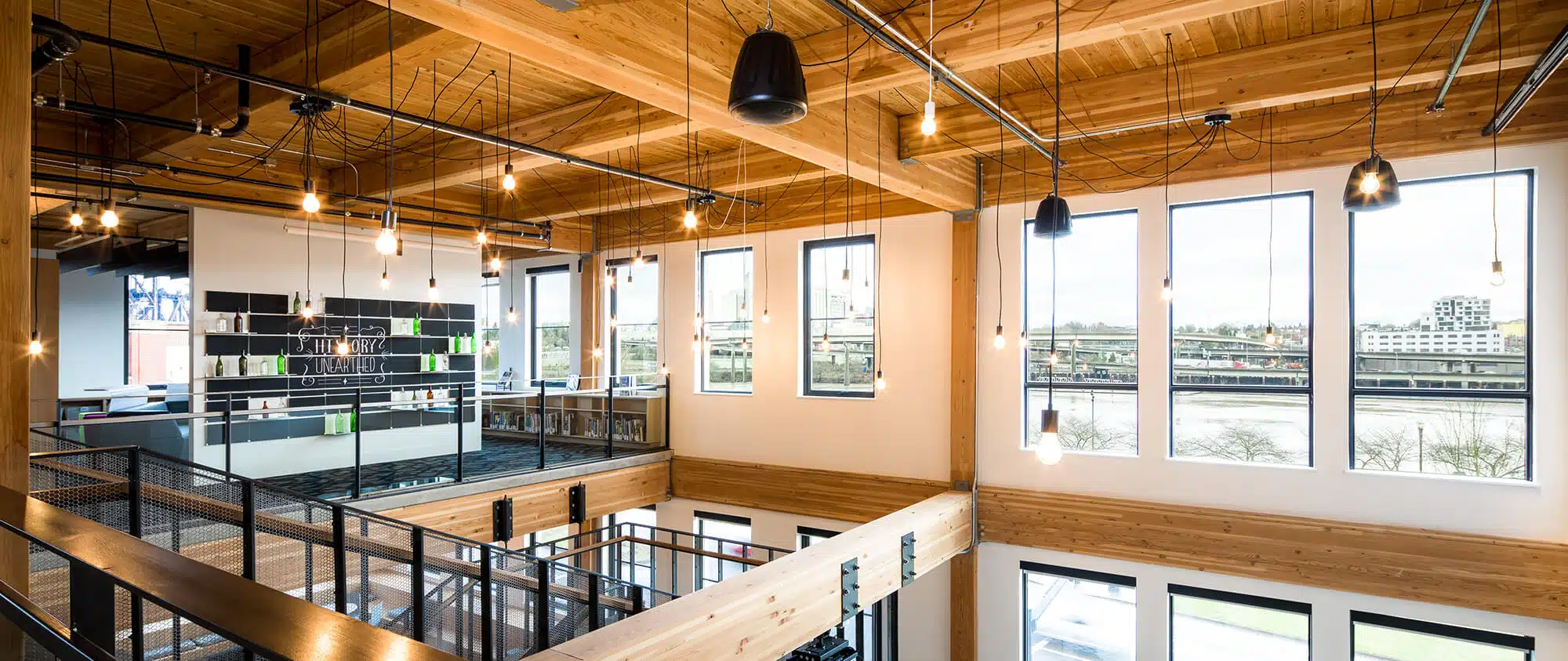

Tailored to meet your unique vision, each piece is meticulously crafted to transform spaces into works of art. From custom cabinetry and intricate molding to bespoke woodwork solutions, we specialize in bringing your ideas to life with precision and style. Our commitment to quality ensures that every project, big or small, receives the attention to detail it deserves, creating timeless and functional pieces that seamlessly blend into your environment. Discover the artistry of custom architectural millwork, where creativity meets craftsmanship, and your space reflects a true sense of individuality and refinement.

Custom Wall Paneling

Custom Cabinetry

Immerse yourself in the artistry of custom cabinetry, where functionality meets bespoke design. Our Custom Cabinetry services redefine spaces, offering tailored solutions that seamlessly blend form and function. From kitchen marvels to personalized storage solutions, each cabinet is meticulously crafted to reflect your unique style and enhance the overall aesthetic of your space. Whether you crave contemporary elegance or classic sophistication, our skilled artisans bring your vision to life, ensuring that every detail is a testament to precision and quality. Elevate your surroundings with the timeless allure of custom cabinetry, where innovation meets craftsmanship, and your space becomes a reflection of personalized luxury.

What is architectural millwork?

One prominent category within architectural millwork is custom cabinetry, where tailor-made cabinets, shelves, and storage units are crafted to fit specific spaces and purposes. These elements not only provide practical storage solutions but also serve as integral components of the interior design, reflecting a seamless blend of form and function. Another crucial aspect is wood paneling, which transforms walls into textured canvases, ranging from traditional raised paneling to contemporary, sleek designs. The versatility of architectural millwork allows for the creation of built-in furniture, such as bookshelves and entertainment centers, seamlessly integrated into the structure for a cohesive and customized look.

Architectural millwork extends to doors and windows, where custom-made pieces with intricate detailing enhance both functionality and visual appeal. Staircases and railings, often crafted with precision, contribute to the overall design aesthetic and create a lasting impression. Columns, whether purely decorative or structurally significant, showcase the artistry involved in architectural millwork. Specialized elements like fireplace mantels and coffered ceilings further demonstrate the range of possibilities within this craft. In essence, architectural millwork is a bespoke art form that elevates the interior environment, offering a personalized touch that aligns with the design vision and style preferences of a space.