No experience working with a custom furniture maker to make your dreams come true? Here’s how we do it, step by step.

As with any creative pursuit, every person – or group – will take a different approach to collaboration and creation. Ours at RFP Design Group Inc. has always placed the client at the centre of what we do and how we do it. We know that this process is never the only thing on our clients’ plates – from a whole network of moving parts to manage in a construction project, to the day-to-day tasks of balancing work, life, and home. Through every step in the RFP process, we’re not only thinking about the final product – but how to make the journey to that product as enjoyable as possible and the best custom furniture maker.

- Vision & Estimates: It all begins here, with an initial meeting with the team at RFP, whether that’s through our simple online order system or by contacting us for a consultation meeting in person.

- If you have a residential project in mind, all you need is an idea of what you want, basic dimensions, and some inspiration material: photos, mood boards, references, even fabric, metal, or wood samples if you have them. In this meeting, we may ask you about your lifestyle, interests, style sensibility or more to learn more about you – we want to make sure we are designing the perfect piece to work in your home life.

- If you’re working on a commercial space, usually our clients have a very specific idea in mind. We’re very experienced with this style of collaboration as well and will follow the lead of the designer.

- Material Selection: Whether you’re designing for a commercial or residential space, all of our clients have access to RFP’s premiere selection of materials, including: a vast but curated fabric collection, wood or metal samples in an assortment of finishes from elite suppliers, a variety of foam or down fillings and a selection of tufting options, and a range of high-quality seam types completed in our state-of-the-art fabrication facility in Mississauga, Ontario.

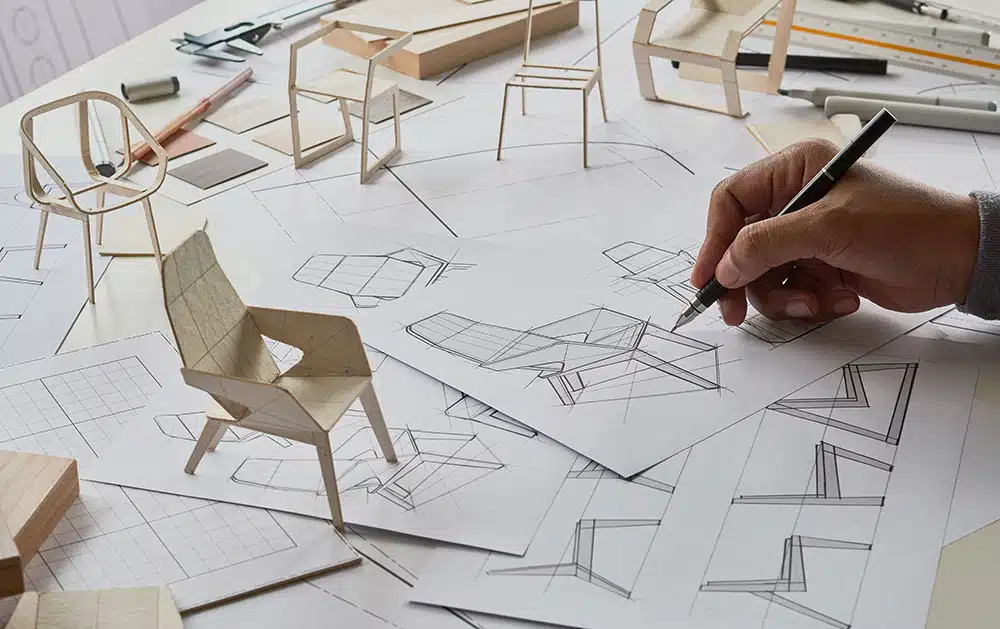

- Design Renderings: After both the client and the RFP team is happy with the overall design direction and chosen materials, we enter the design rendering phase. Using programs like SolidWorks, Lectra, and AutoCAD, RFP designers and engineers will build a digital 3-D image of each piece for final approval of measurements, look, and functionality.

- Fabrication: Once the 3-D renderings are approved, RFP will produce the piece – from mockup to the final piece – inside our fabrication facility. It is RFP’s mission to be as transparent as possible through the process, beginning with a prototype if needed, and always providing progress photos and documentation to our clients. If any issues or questions arise along the way, we will be in full communication with the client and offer our expertise to find a solution that works for everyone.

- Delivery: RFP will never send a piece out the door without a final once-over from our quality control team. Perfection is our standard – and they look for just that. Luckily, it’s extremely rare not to hit that goal. Once approved, our delivery team carefully packs up and delivers the finished order.

RFP is a full-service custom furniture fabricator – from the initial design consultation to final pickup or delivery – and we operate with our client at the heart of every step. Get in touch today to see how we can help you with your next project!